it is used for EVA、PE、CR、EPDM、SBR foaming products.

2.Parameters:

|

Model |

Clamping Force(Tons) |

Platen Size (mm*mm) |

Layers |

Daylight (mm) |

Distance between Columns (mm) |

Diameter of Piston (mm) |

|

JHF-22 |

500 |

900*1200 |

4 |

150 |

1300 |

560 |

|

JHF-26 |

700 |

1100*1350 |

6 |

150 |

1400 |

650 |

|

JHF-30 |

900 |

1200*1500 |

6 |

150 |

1600 |

762 |

|

JHF-33A |

1100 |

1300*1600 |

6 |

170 |

1600 |

838 |

|

JHF-33B |

1100 |

1350*1700 |

6 |

170 |

1800 |

838 |

|

JHF-36 |

1350 |

1350*1800 |

6 |

180 |

1800 |

915 |

|

JHF-40 |

1650 |

1400*2200 |

6 |

180 |

2000 |

1016 |

|

JHF-44 |

2000 |

1400*2400 |

6 |

200 |

2000 |

1100 |

A.Strong structure

The frame is strong enough to make sure the the material would not be come out.

B.Fast open

The molds could be open in 1s to make sure the cell in the foam is uniform.

C.Uniform temperature

The temperature difference could be controlled in ±1℃, so that the color of the sheet is uniform.

D.Automatically control

We use PLC to control the system and the whole process could be automatic or manual controlled.

4.Options

-

Yoga mat

-

Puzzle

-

Floating Mat

-

Slipper

-

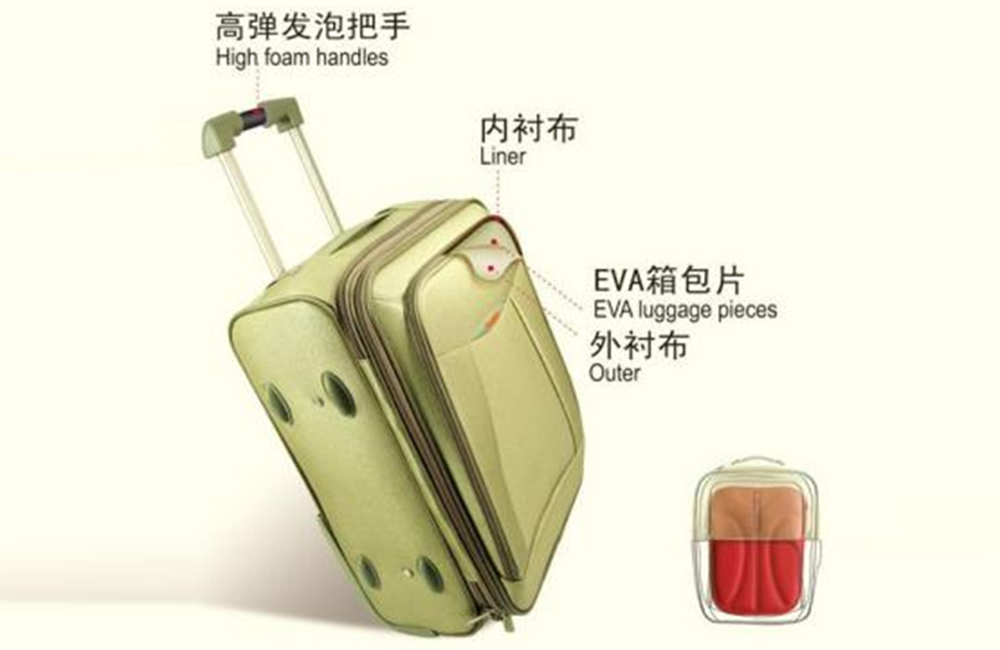

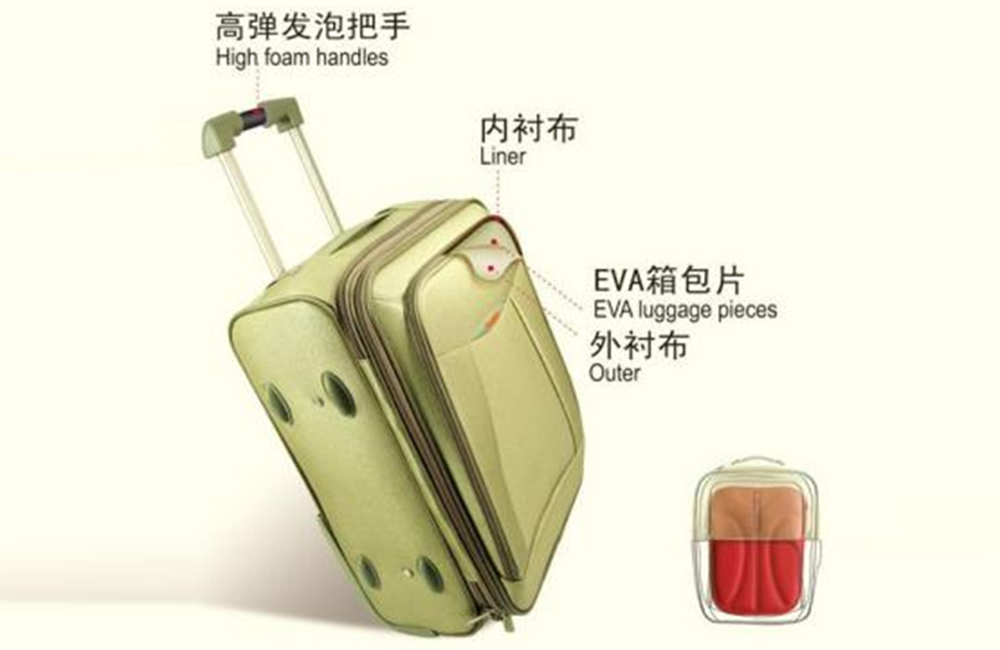

Package foam